Advance Your Career with a World-Class Online Master's Degree from Stevens

A Degree That Pays Dividends

Stevens is consistently recognized for academic excellence and delivering an outstanding return on investment.

#1

Online MBA from a New Jersey school in 2025(U.S. News & World Report)

#7

Best Online Master's in Engineering Management Programs nationally(U.S. News & World Report (2026))

7x

Winner of the 21st Century Award for Best Practices in Distance Learning(USDLA)

#9

Ranks No. 9 among 'Best ROI Colleges'(*Based on the cost of a four-year bachelor's degree program)

Discover Your Future at Stevens

Watch how Stevens Online transforms careers through innovative education, expert faculty, and flexible learning designed for working professionals.

THE STEVENS ONLINE ADVANTAGE

Our Online Master’s Degree Programs are designed to provide the same quality as our highly-ranked on-campus programs. We offer relevant courses, renowned faculty, and individualized support to each student.

Additional benefits of our StevensOnline programs include:

- Global cohort of classmates to learn with and from

- Direct access to experienced faculty

- Flexibility for how and where you study

Through our online offerings, you will gain access to the same quality programs and distinguished faculty as on-campus students.

ONLINE MASTER OF SCIENCE IN COMPUTER SCIENCE

Ranked No. 11 in New Jersey for Best Online Master's in Computer Information Technology Programs by U.S. News & World Report (2024), the online computer science master's program at Stevens offers you a curriculum aligned with high-demand areas such as software development, web programming, mobile systems and applications, cloud computing, human-computer interaction, and enterprise software design.

ONLINE MBA

The Stevens Online MBA is an AACSB-accredited program offered part time through online courses. The Online MBA combines business knowledge with the technology and analytics necessary to excel in today's data-centric world. Students will build upon their managerial toolkits with analytical, data literacy, marketing and operations management skills that drive data-based decisions.

ONLINE MASTER OF ENGINEERING IN ENGINEERING MANAGEMENT

Master the ability to interface between technology and business stakeholders. This program will advance your understanding of the technology involved in engineering projects and the management process through which the technology is applied. Graduates from the Online Master of Engineering in Engineering Management program are prepared to add value at the intersection of engineering and management and assume professional positions of increasing responsibility.

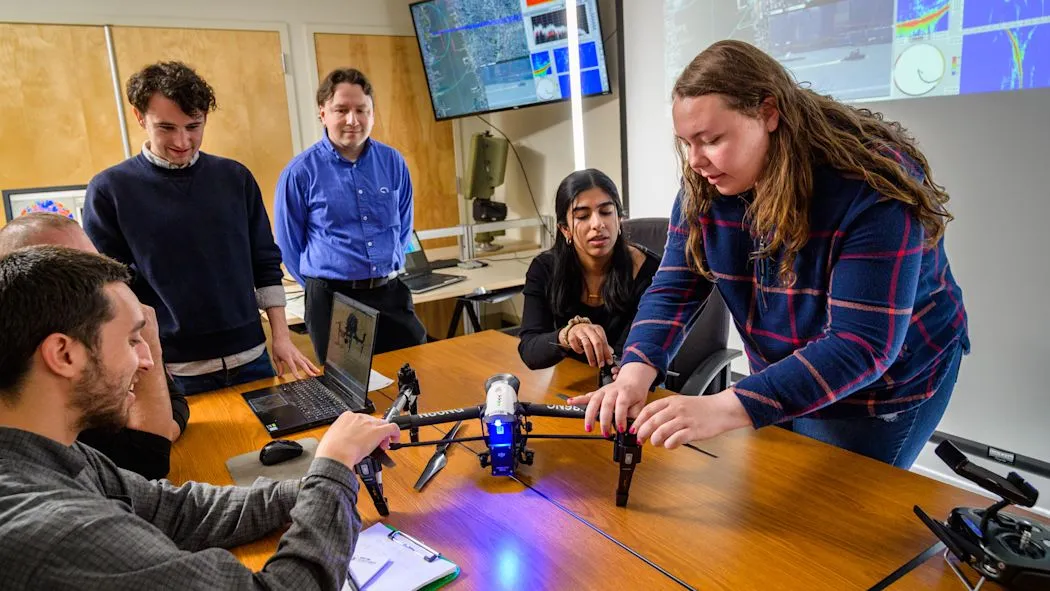

A Legacy of Innovation Meets Online Flexibility

At Stevens, you don't have to choose between a prestigious degree and a flexible online format. Our programs are designed for working professionals, offering the same rigorous curriculum and world-class faculty as our on-campus degrees. You'll gain career-ready skills and join a powerful alumni network, all on your schedule.

A Community That Supports Your Success

From your first inquiry to graduation and beyond, you are a valued member of the Stevens community. Our dedicated enrollment advisors, student support services, and active alumni network are here to help you achieve your goals. Engage with faculty and peers in a collaborative online environment built for connection.

"Stevens Online is dedicated to delivering world-class technology education to working professionals worldwide, empowering them to advance their careers and drive innovation in tomorrow's digital economy through flexible, accessible, and industry-relevant online programs."- Arshad Saiyed

Chief Online Learning Officer and Dean of the College of Professional Education

Key Dates & Deadlines

Plan your application for the upcoming Spring II 2026 term.

| Term | Early Submit | Priority Submit | Final Submit | Start of Classes |

|---|---|---|---|---|

| Spring II 2026 | January 31, 2026 Deposit Waiver* and Application Fee Waiver Available. | March 1, 2026 Application Fee Waiver Available and Early Application Review. | March 7, 2026 | March 17, 2026 |

Latest from Our Blog

Stay informed with insights, tips, and news about online education, career advancement, and technology trends.

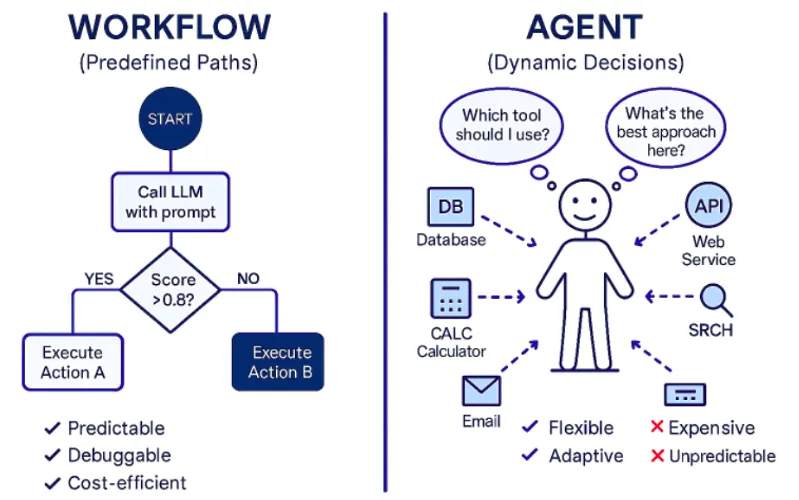

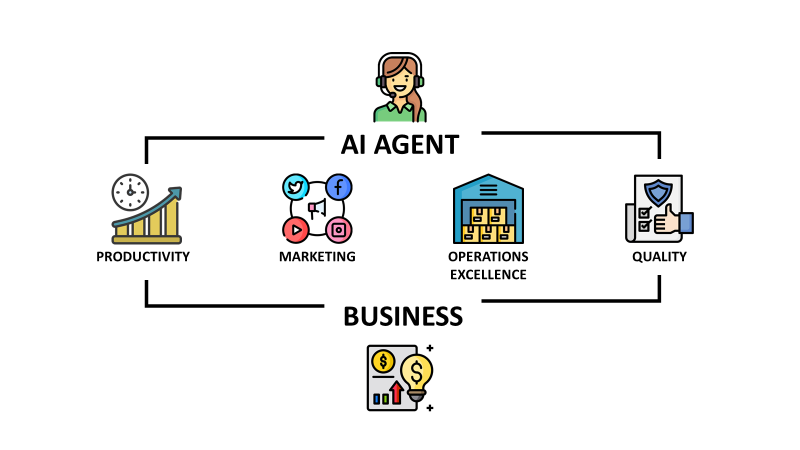

The Agentic Shift: Why Reliable AI Depends on Architecture, Not Bigger Models

The artificial intelligence landscape is undergoing a fundamental transition. We are moving from stateless, prompt-based interactions to stateful, autonomous agentic systems. This evolution represents a departure from viewing Large Language Models as solitary oracles to treating them as cognitive engines within broader, engineered systems.

Building Self-Healing AI: The Orchestrator-Workers and Reflexion Patterns

To operationalize the agentic shift, developers and architects are coalescing around specific design patterns. These patterns solve the fundamental problems of coordination, error handling, and task decomposition that plague traditional AI implementations.

The Hidden Economics of AI Agents: Managing Token Costs and Latency Trade-offs

The shift to agentic AI is not just technical. It is economic. The cost model of software is changing from fixed infrastructure to variable intelligence, and engineering leaders must understand the hidden economics that can make or break an AI deployment.